Normally, using diamond saw blades with adequate water (wet cutting) can extend the blades’ life and control dust. However, in some situations, dry cutting should or has to be performed. These situations include:

For some electrical power tools, it is not safe to use water because of the electrical power source.

The work area needs to be kept dry.

Water source is not available near the work area.

1. Choose proper dry-use diamond blades

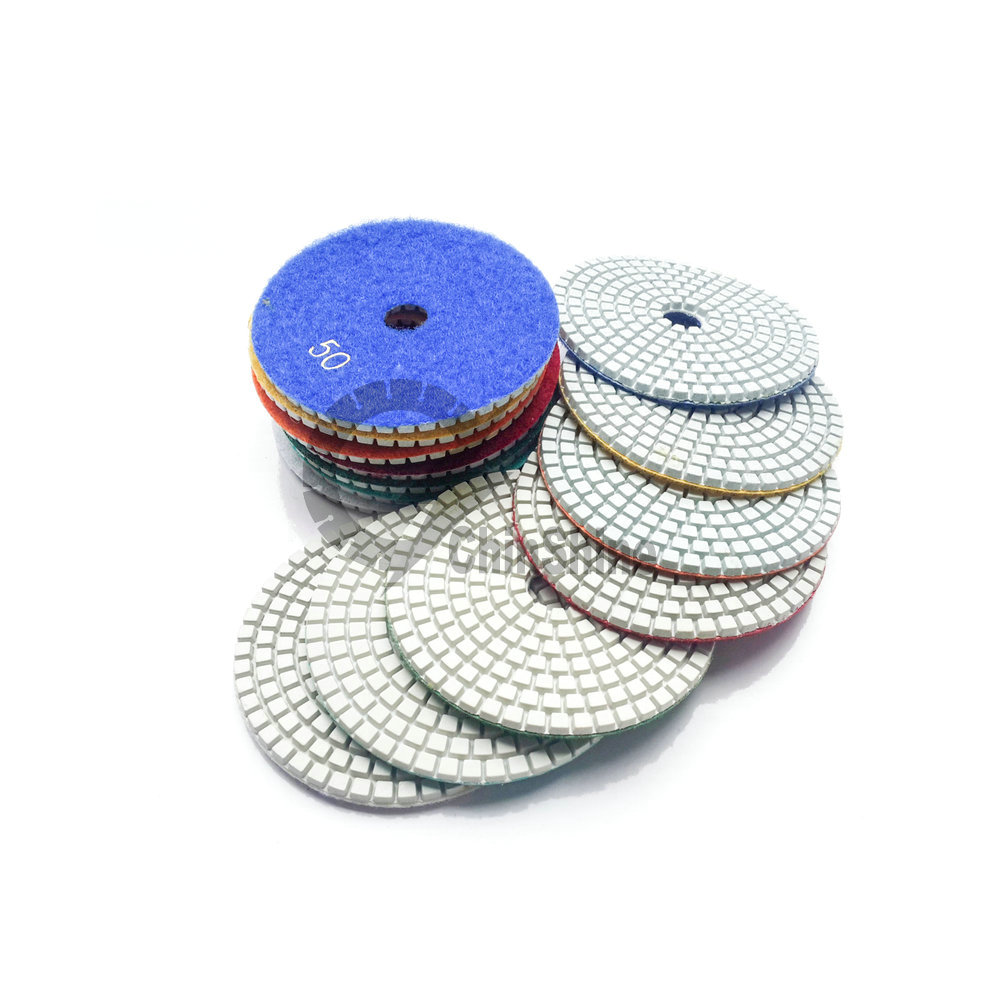

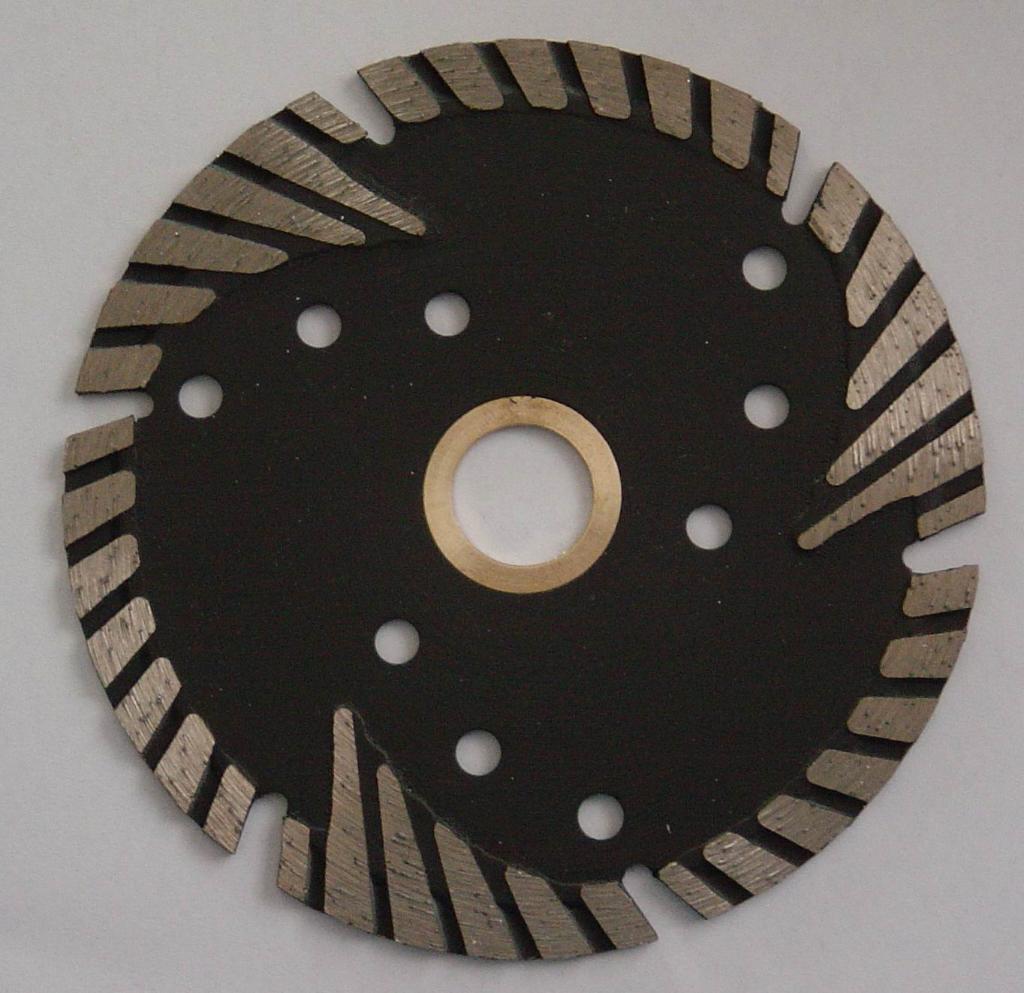

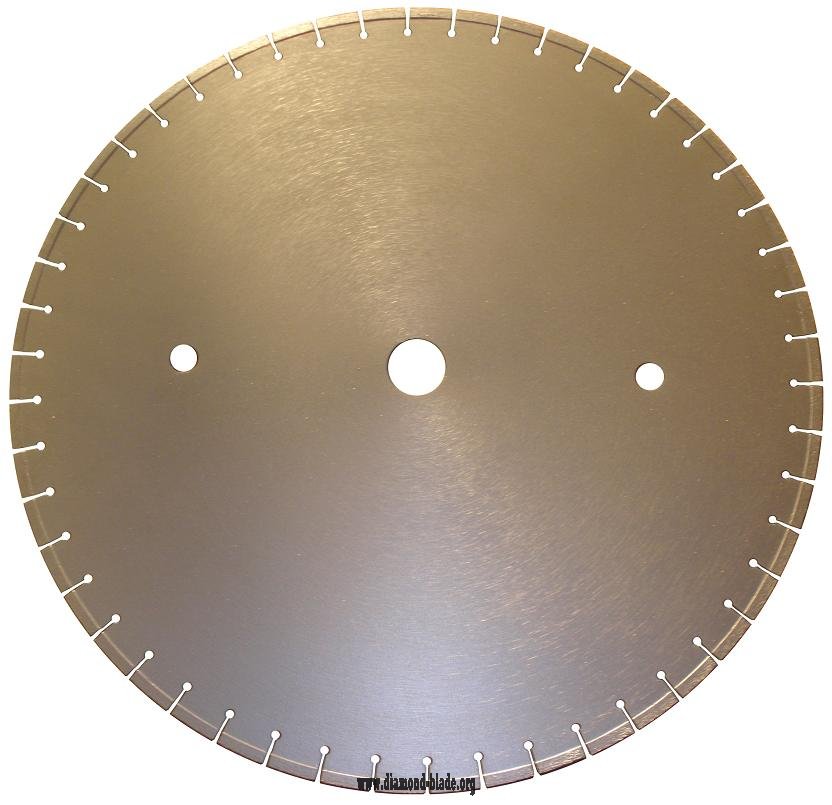

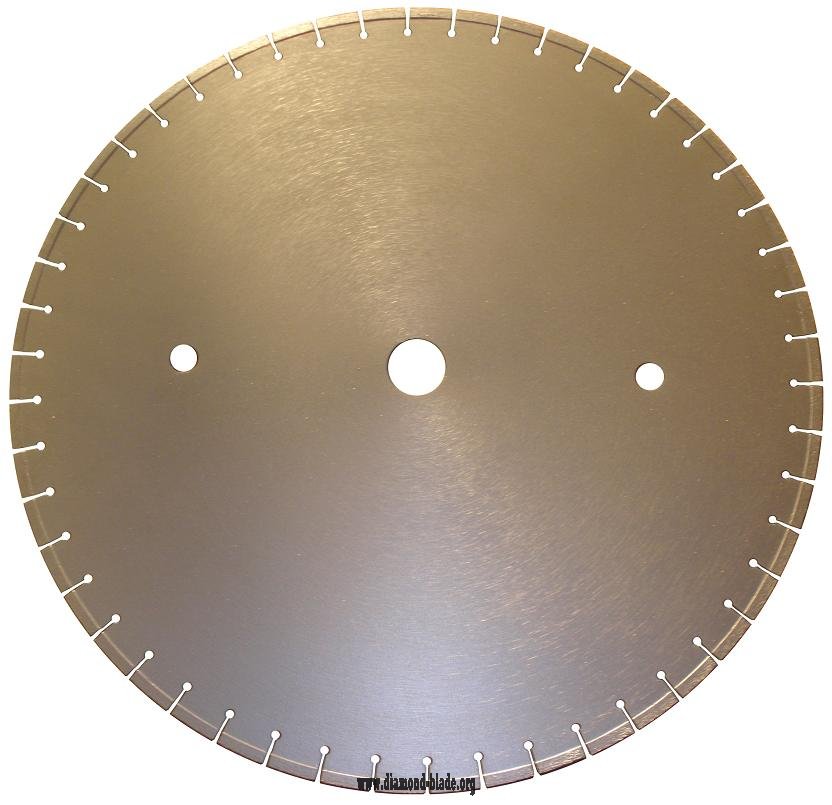

If you need to perform dry cutting, you should first choose the proper diamond blade which can be used dry. Diamond blades for dry use are normally different from the ones only for wet use. For sintered diamond blades , continuous rim diamond blades are usually only for wet cutting. Most of other sintered diamond blades can be used dry. For welded diamond blades, silver brazed diamond blades cannot be used in dry cutting, while dry-use laser welded diamond blades can. You can read our diamond saw blades introduction article for more information. Dry-use laser welded diamond blades are designed different from the laser welded diamond blades that are only for wet use.

Dry diamond blades usually can be used wet. But if a wet diamond blade is used with inadequate water or even dry, the diamond blade may be overheated and damaged, and even worse, the segment on the blade may break and fly out, and may hurt the operator or the people nearby.

So tell your diamond blade supplier that you need dry cutting, and let him/her choose proper dry diamond blades for you.

2. Operate dry diamond blades properly

After obtaining a right diamond blade for dry use, if the operator fails to operate properly, the excessive heat generated in the dry cutting process may still damage the diamond blade, and the operation can be very dangerous.

Unlike wet cutting using water as the coolant, dry cutting uses air to cool the diamond blade. During dry cutting, the operator should perform intermittent and shallow cuttings to allow the air to flow around the diamond blade.

Intermittent Cutting:The operator should not do long time continuous dry cuttings. Instead, after some time of dry cutting, he should take the pressure off the diamond blade, and let the blade run freely and to its full speed to allow the air to keep it cool. The duration of each dry cutting operation can be a few minutes to a few seconds depending on the hardness of the material being cut. The harder the material, the more often the diamond blade should be allowed to cool.

Shallow Cutting:The operator should also perform shallow cuttings to avoid the diamond blade’s overheating. When deep cut is needed, he can do several passes of shallow cuttings (step cut) to achieve it.

Do not force wall saw blade into the material:The operator should allow the diamond blade to cut at its own speed. Forcing the blade may cause overheating and blade damage.

More information, if you experience problems with wobbling when performing dry cutting with a high-power handheld saw machine, try wet cutting. This can cool down the diamond blade and solve the problem. Not all materials can be cut dry. Very hard materials, for example, concrete with strong reinforcement, should still be cut with adequate cooling water. For concrete saws, wet cutting is preferable as it allows continuous and deeper cuttings, reduces the dust, and can prolong the diamond blade’s life.

Related Articles:

a. How do people suggest buying diamond saw blades?

b. How do you choose the right diamond saw blade?

c. Buy Concrete Diamond Blades for Building Contractors.

d. Concrete diamond blade cutting Safty Guidelines

Related Articles:

a. How do people suggest buying diamond saw blades?

b. How do you choose the right diamond saw blade?

c. Buy Concrete Diamond Blades for Building Contractors.

d. Concrete diamond blade cutting Safty Guidelines

Previous:Silver Brazed and Laser Welded Diamond Saw Blades Next:Diamond Tools Inquiry from a Famous company

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|