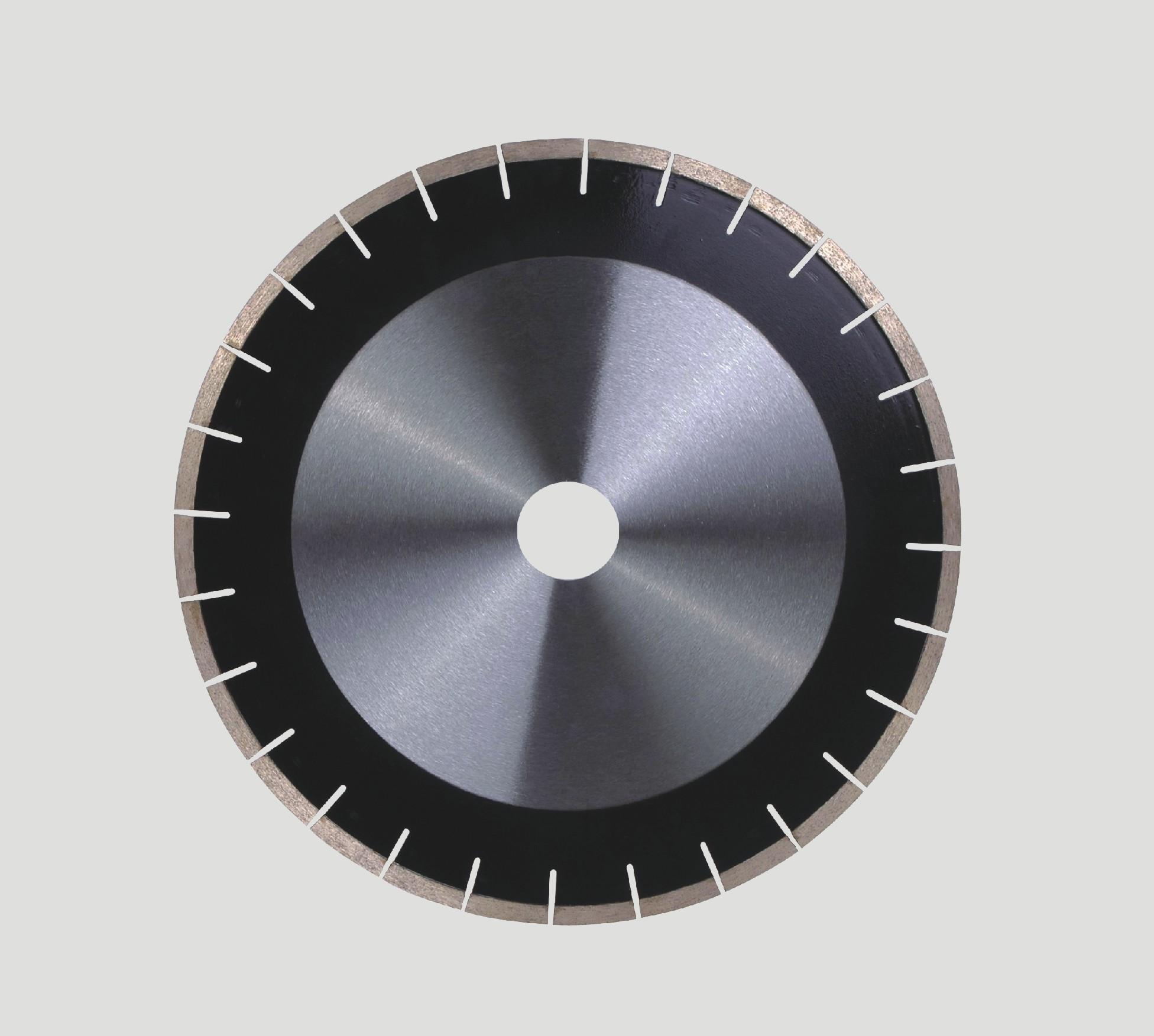

The head of saw blade is usually made by cemented carbide like YG or YT. Because YG is better of impact resistance, it is used in wood processing industry more widely. The more cobalt content in the alloy, the higher impact resistance and bending strength it has, but at the same time, the hardness and abrasion resistance will fall. So it's better to consider the practical application accordingly when choose the saw blade.

To choose the saw blade, it's better to consider the type, base materials, diameter, number of teeth, thickness, tooth shape, angle, aperture and other parameters which determines its processing capacity and cutting performance. We can divide saw blades into different classifications according to the material, thickness, sawing speed, sawing direction, feeding speed and kerf width of the workpiece for processing. Based on applications, saw blades can be classified as blades for milling cutters, pipe cutting, woodworking or stone cutting. There are also metal-specific blades (such as saw blade used for cutting aluminum, copper and stainless steel, etc.) and tile saw blades.

Choose Saw Blades According to the Performance Requirements

Choice of Base Materials

Spring steel is good for its good elasticity and plasticity. Its heated temperature is low and easy to deform. The material is economic. So it can be used to make saw blades for workpiece with lower cutting requirements.

Carbon steel has high carbon content and thermal conductivity. But its hardness and abrasion resistance fell sharply at the temperature between 200 ℃ and 250 ℃. During heat treatment, it's easy to deform and crack with long tempering time and poor quench-hardening ability.

To compare with carbon steel, alloy steel has better heat resistance, abrasion resistance and treatment performance. It'll deform at the temperature between

300 ℃ and 400 ℃. So it is suitable for manufacturing high-grade circular alloy saw blades.

High-speed steel has good quench-hardening ability, strong hardness and rigidity with less heat-resistant deformation. It is a kind of high-duty steel with stable thermoplasticity. So it is suitable for manufacturing high-grade ultra-thin circular saw blades.

Choice of Diameter

Diameter of saw blades is relevant to the thickness of sawing equipment and workpiece. Cutting speed is relatively lower with smaller diameter. Blade of large diameter has higher requirements to the saw blade and sawing equipment. At the same time, the sawing efficiency is higher. Outer diameter of blade requires corresponding saw blade according to different circular sawing machine models.

Choice of Teeth Number

Generally speaking, the more number of teeth there are , the more cutting edges there will be in unit of time, and the cutting performance is better. But more cemented carbide is needed, and the price of saw blade is higher. If the distance between saw teeth is too close, the tolerance of the flocks will become smaller, the blade will be easy to fever. Furthermore, if there are too many saw teeth, the friction between blade edge and workpiece will increase when feeding mismatches, thus affect the service life of the blade.

Choice of Thickness

The thinner thickness of the saw blade is, the better the blade will be in theory. Saw seam is actually a consumption. Base materials and manufacturing process determine the thickness of alloy saw blade. When we choose the thickness, we should consider the working stability and materials of the workpiece.

Choice of Tooth Shape

Usually, there are tooth types like alternate tooth, smooth tooth, ladder flat tooth (high and low tooth), inverted cone tooth and hump tooth, etc.

Choice of Sawtooth Angle

Parameters of sawtooth angle are very complex, and also the most professional. The decisive key to the sawing quality is to choose the right angle parameters. The main parameters are the former angle, clearance angle and wedge angle.

Choice of Aperture

Aperture is a relatively simple kind of parameters. It is chosen according to the requirements of the equipment. But in order to maintain the stability of the blade, it's better to choose circular saw blade with diameter of more than 250mm for the equipment with larger aperture.

Previous:Manufacturing method of diamond saw blade Next:What is sandwich diamond segments? why do we use sandwich segments?

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|