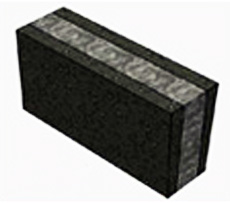

Just as its name implies, the structure of diamond segments which are welded by silver solder tabs on the circular saw blade is like "sandwich". The 3 layers of segment is compressed tightly by high temperature, the layers are bilatere highly hard diamond and a softer metal layer in the middle. This diamond segment has obvious feature to traditional diamond segment.

The purpose of designing such structure "sandwich" diamond segment is to keep balance during the stone cutting and make sure the stone edge is not declining. The operational principle is like this: the bilatere diamond layer is harder than the metal layer in the middle, when cutting the stone, these 2 layers receive little abrasion and then become sharp "knife", it brings easy cut-in. The metal layer is a bit softer in the middle, it assists cutting, finally the blade will goes in the ready routin and makes the cutting straight, the planeness of the slab and tile is greatly improved.

Earlier diamond segment of diamond circular blades was designed to be even cuboids. Later, people found that, after a period of sawing, the two sides of the segments are easier to be worn than the middle, and the segments become a convex shape. The convex-shape diamond segments have a larger contact area with the material being cut, therefore the diamonds on them are easier to be ground blunt and then need dressing. In addition, as the sawing force will also increase, the core of the diamond blade tends to be distorted and be deformed for vibrations. This can influence the cutting precision, and reduce the blade core’s service life. Sandwich diamond segments, which have higher side layers and lower middle layers, however, can solve this problem to a great extent.

Sandwich diamond segments can be made via the following methods:

The diamond concentration in side layers is higher than the one in middle layers.

The bond material in side layers is more wearable than the one in middle layers.

The diamond’s grade in side layers is higher than the one in middle layers.

Make the working length of middle layers shorter than the one of side layers via structural designing.

Add non-working layers into the multi-layer structure, and adjust the width ratio of working layers and non-working layers.

Related Articles

a. What is the diamond segment welding technique?

b. Why shouldn’t you buy VERY cheap diamond diamond segments?

c. How do you choose the right diamond saw blades and diamond segments?

Previous:Choice of Saw Blades Based on Applications Next:Marble cutting with single point cutting tool and diamond segments on Frame saw

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|