Firstly, start with the diamond steel wire abrasive brush, make sure to remove all marks and dirty on the surface, if any marks were left on the granite surface, you will see them in the finish of granite slab. Then follow with the diamond abrasive brush.

In view of different stone and customers’ preference, stone manufacturers add some more abrasive brushes of other grit or get rid of some abrasive brushes in a sequence . There is no limit of brush grit to use, only after test and experiment; you will know what effect you like.

Always check to make sure each step has time to clean the previous dirty, especially after the metal steel wire brush. The brush scratch marks if not removed will stand out in the final finish.

If you have questions, comments or want to know more, please contact us: sales@diamond-blade.org

- * It is easier to brush the granite that has large & small grain than tight grain. Granite which has tight grain needs to be flamed first, such as absolute black granite, G654, Shanxi Black.

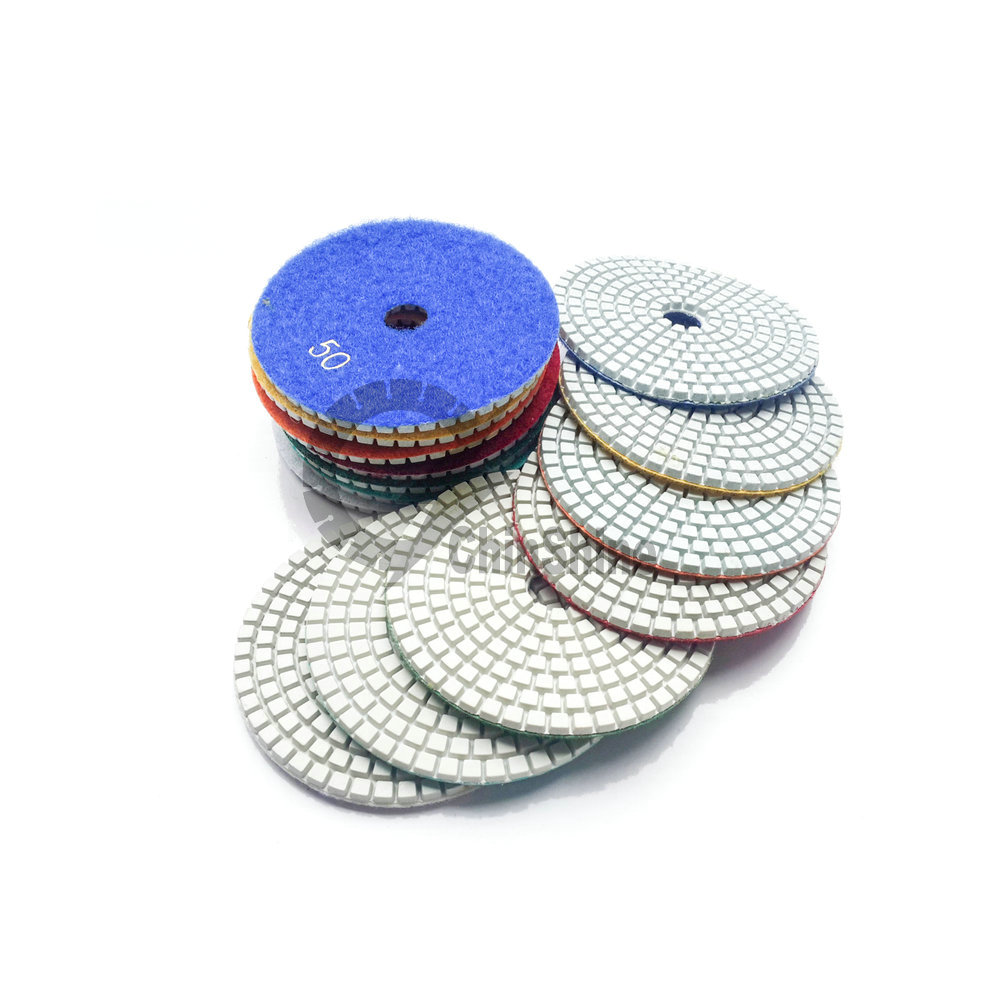

- * For the hard granite – The abrasive brush will speed the process. ChinShine abrasive brushes are available in #36, #46 and #80, all three types don’t need in a sequence to brush, it depends on the granite hardness and to the effect desired in the end finish. But in most cases with the diamond abrasive brushes on granite, the more cycles, the deeper the texture.

- * Now use the grit 36 fickert abrasive brushes, this step will determine the finish look, more cycles the deeper the look, there’s no standard here, only preference. (multiple headed machines use 2 or 3 heads of the #36)

- * Follow with the #46, 2 cycles will always help; it just makes the surface a smoother more flowing look.

- * Process the surface like below:

- #80 – 1 cycle

- #120 – 1 cycle

- #180(or #160) – 1 cycle

- #320 – 1 cycle

- #500 – 1 cycle

- #800 – 1 cycle for more color

In view of different stone and customers’ preference, stone manufacturers add some more abrasive brushes of other grit or get rid of some abrasive brushes in a sequence . There is no limit of brush grit to use, only after test and experiment; you will know what effect you like.

Always check to make sure each step has time to clean the previous dirty, especially after the metal steel wire brush. The brush scratch marks if not removed will stand out in the final finish.

If you have questions, comments or want to know more, please contact us: sales@diamond-blade.org

Previous:What elements lead to slow cutting speed of diamond saw blade Next:The development of Chinese diamond tools industry

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|