When cutting concrete with diamond blade, several parameters influence your choice of a diamond blade. These include compressive strength, cobblestone, hardness of the aggregate, size of the aggregate, type of sand, steel reinforcing and new or cured concrete.

The guidelines in this section are for general reference only. Your best source for information on the characteristics of the concrete you are cutting is from the original contractor. Contact your local Department of Transportation or City Hall for help in tracking down this information.

Compressive Strength

Concrete slabs may vary greatly in compressive strength, measured in pounds per square inch (PSI).

| Concrete Hardness | PSI |

|---|---|

| Critically Hard | 8,000 or more |

| Hard | 6-8,000 |

| Medium | 4-6,000 |

| Soft | 3,000 or less |

Most concrete roads are 4-6,000 PSI, while typical patios or sidewalks are about 3,000 PSI.

Hardness of Aggregate

There are many different types of rock used as aggregate. Hardness often varies even within the same classification of rock. For example, granite varies in hardness and friability.

The Mohs scale is frequently used to measure hardness. Values of hardness are assigned from one to ten. A substance with a higher Mohs number scratches a substance with a lower number - higher Mohs scale numbers indicate harder materials. The scale below shows how some common minerals fall into the Mohs scale range.

| Mohs Scale | ||

|---|---|---|

| 1-Talc | 5-Apatite | 9-Corundum |

| 2-Gypsum | 6-Feldspar | 10-Diamond |

| 3-Calcite | 7-Quartz | |

| 4-Flourite | 8-Topaz | |

Most aggregates fall into the 2 to 9 range on the Mohs scale. Some commonly used aggregates measure this way on the Mohs scale:

| Mohs Range | ||

|---|---|---|

| Range | Description | Aggregates |

| 8-9 | Critically Hard | Flint, Chert, Trap Rock, Basalt |

| 6-7 | Hard |

Some River Rock, Some Granites, Basalt, Quartz, Trap Rock |

| 4-5 | Medium Hard | Some River Rock, Some Granites |

| 3-4 | Medium |

Dense Limestone, Sandstone, Dolomite, Marble |

| 2-3 | Medium Soft | Soft Limestone |

Aggregate hardness is one important factor when cutting concrete. Because hard aggregate dulls diamond grit more quickly, segment bonds generally need to be softer when cutting hard aggregate. This allows the segment to wear normally and bring new, sharp diamond grit to the surface. Softer aggregate will not dull diamond grit as quickly, so harder segment bonds are needed to hold the diamonds in place long enough to use their full potential.

Size of the Aggregate

The size of aggregate affects diamond blade performance. Large aggregates tend to make a blade cut slower. Smaller aggregates tend to make a blade cut faster. The most common standard sizes of aggregate are:

- Pea Gravel – variable in size, usually 3/8” or less diameter

- ¾” – sieved size

- 1 ½” – sieved size

Type of Sand

Sand is part of the aggregate mix, and determines the abrasiveness of concrete. "Small aggregate" is usually sand. Sand can either be sharp (abrasive) or round (non-abrasive). To determine the sharpness of sand, you need to know where the sand is from. Crushed sand and bank sand are usually sharp; river sand is usually round.

Green concrete is more abrasive than cured concrete. When the concrete is not fully cured sand can more easily be scraped off the surface being cut. More loose sand means more abrasiveness.

Amount of Steel Reinforcing (Rebar)

Heavy steel reinforcing tends to make a blade cut slower, while less reinforcing tends to make a blade cut faster. "Light" to "heavy" rebar is a very subjective term. Examples include:

| "light" | Wire mesh, single mat |

| "Medium" |

#4 rebar, every 12" on center each way (OCEW), single mat wire mesh, multi mat |

| "Heavy" |

#5 rebar, 12" OCEW, single mat #4 rebar, 12" OCEW, double mat |

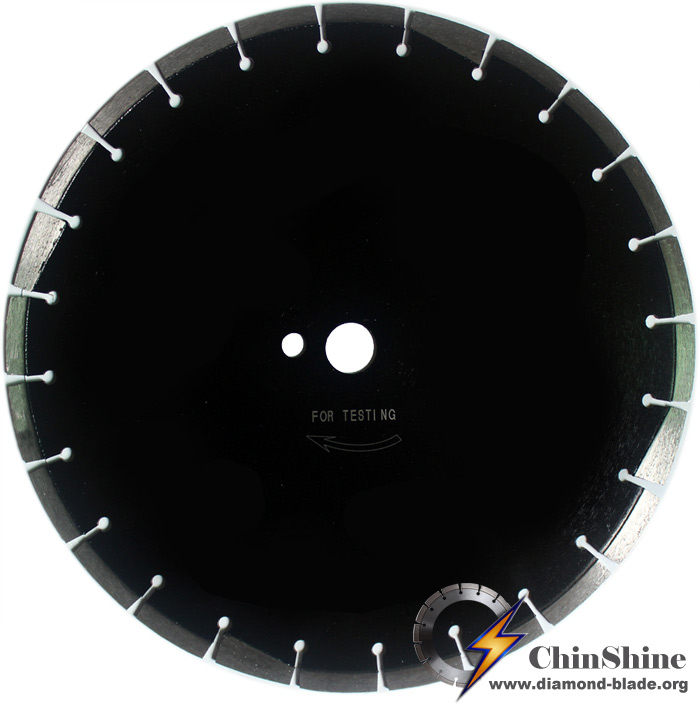

Green or Cured Concrete

The drying or curing time of concrete greatly affects how the material will interact with a diamond blade. Green concrete is freshly poured and has set up, but is not yet fully cured. It is softer and more abrasive than cured concrete. You need a harder bonded blade with undercut protectors to cut green concrete. You need a softer bonded blade to cut the same concrete in a cured state.

Typically, concrete defined as "green" is six hours from pour or younger, but this can vary widely. Weather, temperature, moisture in the aggregate, time of year and the amount of water in the mix all influence curing time. Also, additives in most new concrete can either shorten or extend curing time. Consult your mix design to find the relative curing time for your job. As soon as wet concrete sets up and does not spall or ravel, green cutting can begin.

Previous:Where to Buy Wall and Concrete Cutting Tools? Next:Segmented Diamond Saw Blade and Its Bond

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|