Calibration Diamond Segments for Levelling Granite and Marble

ChinShine makes calibration diamond segments for calibrating or removing raised surface on the stone slab, which is for fixing thickness of slab and prepare for next grinding and polishing steps.

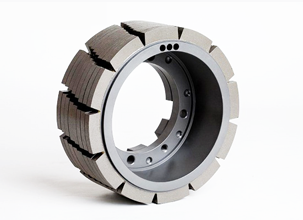

According to the different levelling machines (Calibrating machines), two designs of diamond segment are common in use, one is diamond segments welded onto a steel plate, we call it cubical diamond segments, the Levelling machine (Calibrating machine) works by moving the tiles on a conveyor board, using a series of diamond rollers and pneumatic tools; another one is diamond segment welded on a steel roller, we call it arching diamond segments.

Cubical diamond segments are welded on grinding plate

ChinShine Diamond Calibration Segment Features and Advantages

Perfect surface levelling, high sharpness with aggressive calibration and protrusion stone removal capacity, "fine-honed" surface finish, which makes it possible to reduce the number of following levelling units, and consequently, the dressing costs.The Calibratiing Segment Grain Sizes Available

24#, 36#, 46#, 60#, 80#, 120# or other grits.

ChinShine makes diamond segments for calibrating granite, marble, sandstone, ceramic, quartz stone etc. Any sizes and shapes could be customized.

Diamond Rolls are Installed on Calibrating machine

Diamond Roller

Related Articles:

a. How to Polish and Grind Marble by DIY?

b. Grinding and Abrasive Tools improvement.

c. Where to buy diamond saw blade and diamond tools?

d. Frame Saw for Cutting Granite & Frame Saw Segments

e. Make Drilling Easy And Quick by Using ChinShine Diamond Core Drill Bits

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *