diamond polishing pads, buffing pads, buffing polishing pads, polishing wheels, buffing wheel, buffing pad, polish pad, polisher pads, dry polishing pad, granite polishing pads, concrete polishing pads, floor polishing pads, foam polishing pads

ChinShine Diamond polishing pads introduction:

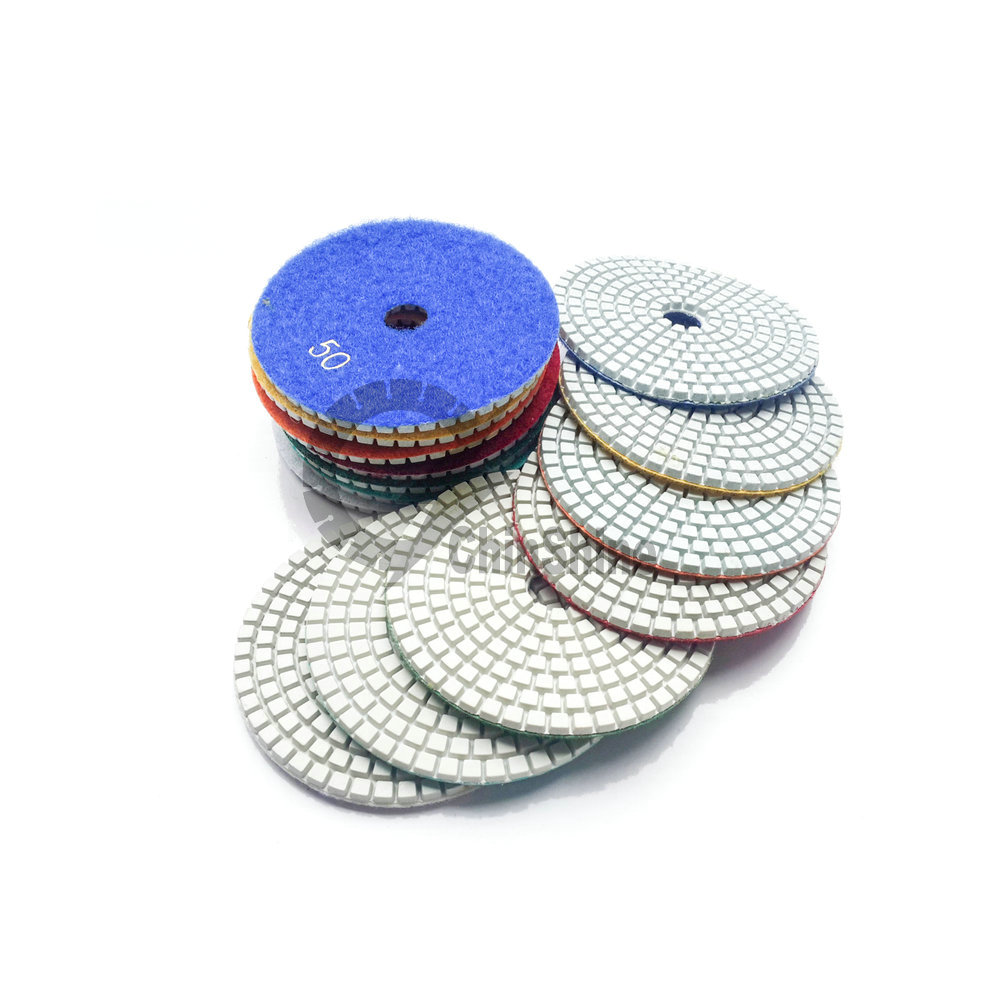

ChinShine offers a complete line of diamond polishing pads for different applications, they can be used in polishing surface and edge of granite, marble, concrete, flooring etc.

* Wet resin bonded diamond polishing pads are generally ideal for polishing granite and marble in stone shops. They are also used for wet polishing of concrete tile and floor.

* Dry diamond polishing pads are used on job sites for polishing marble and granite, while our dry diamond polishing pads are widely used for dry polishing of concrete floors and countertops.

* Metal bond diamond polishing pads are more aggressive. They are used for wet polishing of hard granite and concrete.

We also offer special types of diamond polishing pads including diamond polishing pads for engineered stones.

Diamond Grit: 50,100,200,400,800,500,3000 and buff pads, other grits could be customized.

Color: All Colors are available.

Shape: circular, quadrate, camber and other shapes could be customized.

Size: 3", 4", 5", 6", 7", 8" etc.

The quality of ChinShine Diamond polishing pads:

Our quality is not the best among our competitors around the world, but the quality and price together are the best. In many regions of middle-east, Europe and America, lots of users choose us for their diamond polishing pads supplier, it means that our polishing pads are very competitive.

Our diamond polishing pads are thicker than those from other Chinese manufacturers, and the life is longer than theirs too. We can produce different polishing pads according to different regions and abrasive objects.

How to choose the diamond polishing pads?

The rough and fine diamond grit of a whole set of polishing pad is 50/100/200/400 /800/1500 /3000 and BUFF, these are popular grits, the buff pads are not necessary for some customer. Customers can choose different grits for their abrasive object.

Diamond Polishing pads in grits #50, #100, #200

Such grits polishing pads are for system cleaning, polishing and refinishing floors, without using chemicals polishing, they can be used for natural and synthetic fibers, concrete, stone, granite, marlbe etc.

- quite aggressive

- For the floor heavily damaged

- For polishing tile/slabs after grinded by diamond grinding tools like diamond frankfurt block, diamond fickert brick etc.

- Removes floor scratches and blemishes

- Ideal for floor matting

Diamond Polishing pads in grits #400, #800

- Be used after the coarse polishing

- For cleaning surfaces

- Removeing dirt

- Making light on the floor

Diamond Polishing pads in grits 1500

- Removing fine scratches

- Preparing the fine polishing

- Making light on the floor

Diamond Polishing pads in grits 3000 and polishing buff.

- To make the super fine finishing

- The final polishing

- For the daily care of floor

- Creating the effect of "wet look"

Mostly, diamond polishing pads are generally ideal for polishing granite and marble in stone factory. They are also used for wet polishing of concrete and floor. When polishing, please keep enough water to cool off the diamond polishing pad as the diamonds can't bear overheat, please keep the polishing machine speed lower than 4500rpm.

Related Articles:

a. How to Polish and Grind Marble, concrete and floor by DIY?

b. Buy Concrete Diamond Blades for Building Contractors.

c. Grinding and Abrasive Tools improvement.

-

Tel: +86-595-2288-5227(Ext:2)Mob: 0086-133-2887-5227 WhatsApp/WechatEmail: sales@diamond-blade.org

Tel: +86-595-2288-5227(Ext:2)Mob: 0086-133-2887-5227 WhatsApp/WechatEmail: sales@diamond-blade.orgCopyright © 2006-2024.China(Quanzhou) Diamond Saw Blade Association All Rights Reserved. Email:sales@diamond-blade.org